21 STEAM TRAPS

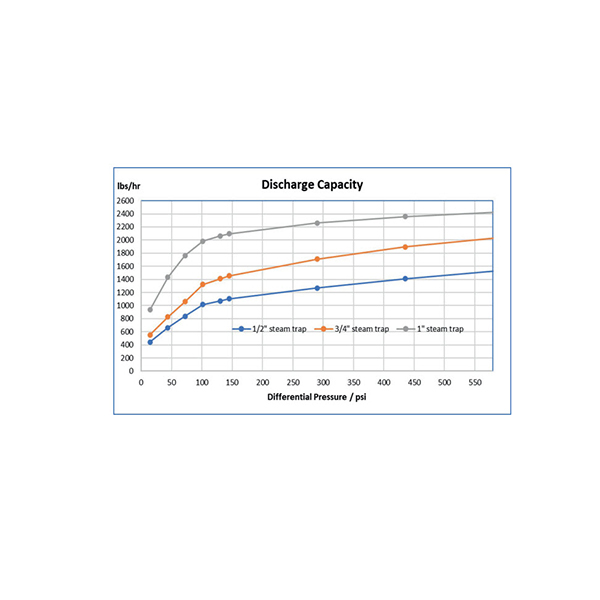

DISCHARGE CAPACITY

STEAM TRAPS

STEAM TRAPS

STEAM TRAPS

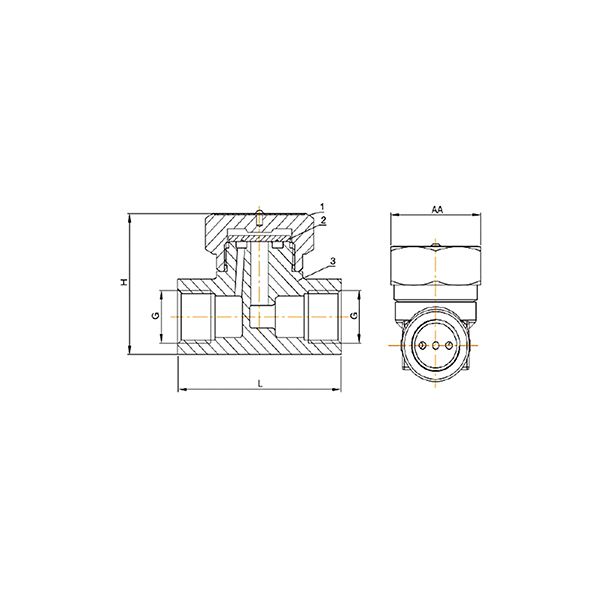

Thermodynamic steam traps play a crucial role in the market industry of Tank Trailers by efficiently managing the flow of steam and condensate. These steam traps are designed to automatically discharge condensate and prevent the loss of valuable steam energy. In Tank Trailers, where steam is used for various applications such as heating and cleaning, thermodynamic steam traps help maintain optimal steam pressure and temperature, ensuring smooth and reliable operation.

By effectively removing condensate, these steam traps prevent water hammer, which can damage equipment and compromise safety. Additionally, thermodynamic steam traps help conserve energy by recovering and reusing valuable steam, reducing operating costs and environmental impact. Their reliability, efficiency, and ability to withstand high-pressure and high-temperature conditions make them essential components in the Tank Trailer industry, ensuring optimal performance and energy savings.

| Part# | Size | Thread | Material |

|---|---|---|---|

| ST-801D15N11 | 1/2" | FxF NPT | Stainless |

| ST-801D20N11 | 3/4" | FxF NPT | Stainless |

- Max Operating Pressure (PSI) 15-600

- Compact Structure

- Easy to repair

- Max Operating Temperature (°F) 400

- Long Service Life

Spinners Rotorjets

Spinners Rotorjets